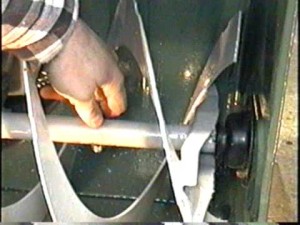

At the very minimum, the spark plug on your snowblower should be inspected every season and replaced as required. Follow the proper safety guidelines as outlined in your manual to ensure that no accidents occur. Changing the spark plug on your snowblower is not difficult. Start by disconnecting the spark plug lead from the spark plug as shown in the picture and remove any debris from around the spark plug before you remove the spark plug from the engine. This will stop any debris from getting into your engine through the spark plug hole.

At the very minimum, the spark plug on your snowblower should be inspected every season and replaced as required. Follow the proper safety guidelines as outlined in your manual to ensure that no accidents occur. Changing the spark plug on your snowblower is not difficult. Start by disconnecting the spark plug lead from the spark plug as shown in the picture and remove any debris from around the spark plug before you remove the spark plug from the engine. This will stop any debris from getting into your engine through the spark plug hole.

Changing the spark plug on your snowblower

Once you have removed the spark plug using a socket wrench, from the engine, use a wire brush to clean the spark plug of any light deposits. You mean need to sand it slightly to remove harder deposits. If there are heavy deposits you may want to replace the spark plug. Once you have cleaned and sanded the spark plug you should regap the plug using a gapping tool to ensure that your spark plug delivers the proper spec for the spark. Note, that it is extremely important to have the correct gap on the spark plug, otherwise your engine may not start at all or run rough due to a poor spark. Reinstall the spark plug and attach the wire.

You will want to test the engine and ensure that it runs smoothly with the new spark plug or the clean old plug. If you have any doubt at all about the spark plug condition replace it with a brand-new one using the recommended spark plug part for your snowblower. Always measure the gap on the plug even if it is a new one and set it to the correct specification for your engine.

Change the Oil in the Engine at the Same Time

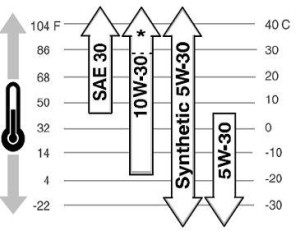

Routine maintenance also suggests that the engine oil should be drained and new oil installed at least once per year and more often if your snowblower is being used a lot. Some snowblower manuals will suggest changing the oil at least once every 50 hours of operation or even more often. Check your manual for the recommended oil change frequency.

Before you open the drain plug, run the engine for a few minutes. This will warm the oil up so that it flows freely. Place a container of some kind under the oil drain spout. Capture the oil and dispose of it in a proper manner. Allow it to drip out until all oil is fully drained. Then reattached the oil plug. Add the proper amount of oil to the engine. Start the engine to allow the new oil to circulate and also warm-up.

Once the engine has run for a few minutes, shut it off, wait thirty seconds, and then measure the oil level to ensure that you have enough oil as recommended by the manufacturer. Add more as needed. If you added too much you will need to drain some off, otherwise, you risk damaging the seals in the engine. For more repair information for your snow blower, click here.

Save

What are the symptoms of bad spark plug in snow blowers? If your engine is not running well, there can be a number of reasons causing this including a bad spark plug. While it might be other items causing the problem, one of the easiest things to check is the spark plug. Remove the plug and clean it, check the gap and replace it. Confirm also that there is a spark between the terminals of the plug. Install the plug and try running the engine to determine if this makes any difference. You will notice right away if this was the problem. Replace overly dirty contaminated plugs with new spark plugs. Set the gap to the proper specifications.

What are the symptoms of bad spark plug in snow blowers? If your engine is not running well, there can be a number of reasons causing this including a bad spark plug. While it might be other items causing the problem, one of the easiest things to check is the spark plug. Remove the plug and clean it, check the gap and replace it. Confirm also that there is a spark between the terminals of the plug. Install the plug and try running the engine to determine if this makes any difference. You will notice right away if this was the problem. Replace overly dirty contaminated plugs with new spark plugs. Set the gap to the proper specifications.