It is the time of year again when we put away our snow throwers or snow blower as some people might refer to them and get ready for the spring and summer. In fact in much of the US and Canada this year, 2012, spring came early and many people have not had to even start their snow throwers since Feb when the last snowstorm occurred. Some folks in the foothills and mountains have received a lot more snow than they wanted, however for the most part consumers in the midwest and the northeast have experienced a very mild winter. It’s time for Snow Thrower Service to ensure your machine is ready for the coming year.

It is the time of year again when we put away our snow throwers or snow blower as some people might refer to them and get ready for the spring and summer. In fact in much of the US and Canada this year, 2012, spring came early and many people have not had to even start their snow throwers since Feb when the last snowstorm occurred. Some folks in the foothills and mountains have received a lot more snow than they wanted, however for the most part consumers in the midwest and the northeast have experienced a very mild winter. It’s time for Snow Thrower Service to ensure your machine is ready for the coming year.

Why would we talk about snow thrower service now especially when our snow throwers have hardly been used? Well, it turns out there are some very good reasons to do your service on your snow thrower this year.

Snow Thrower Service

Here are just a couple of reasons to do it now vs. waiting until next fall when the first snowfall arrives:

- Old gas will clog your carb

- Old oil sludge will harm your engine

- Your engine should be started once every 3 or 4 months

- Service is a lot easier to do when it is warm compared to cold winter days

- Beat the rush to get snow thrower engines tuned up

Drain the Gasoline from the Fuel Tank

With gasoline sitting in your snow thrower’s gas tank and carburetor for a long period of time, the gasoline will deteriorate over time leaving a sticking coating on the engine parts and sometimes clogging the inlets of the carburetor. Left long enough and you will not even be able to start your engine even with a full tank of gasoline. if you have not used your snow thrower since Feb, it could be sitting for 8 to 10 months before it is used again.

At the very least drain the gasoline out of your snow throwers gasoline tank or just run the engine until all of the fuel is used up. This will avoid any chance of the fuel clogging the fuel lines and carburetor. Next season you fill the tank with nice clean and fresh gasoline and you are good to go with your engine. It should start easily once gasoline finds its way into the carburetor.

Change the Oil in the Engine

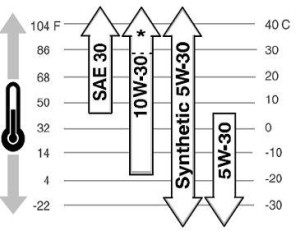

If you are doing an oil change yourself as part of the snow thrower service, follow the instructions in the service manual that came with your snow thrower. Otherwise, make arrangements for a small engine mechanic to service your throwers engine.

There is lots of debate about when you should change the oil in a small engine. Especially if it is not used often. Some people like to change the oil at the end of each season. While others will change the oil just before the season begins. Also, you may want to change the oil if you are a heavy user of your thrower. As a minimum change the oil once per year. Since all oil degrades over time and engine gasses will accelerate this deterioration.

Even if your oil in your engine looks fresh and clean. Maybe you have only used it a couple of times in the past year, change the oil. If you do it yourself the cost is only a couple of dollars and you are ensuring that your snow thrower’s engine will last for many years.

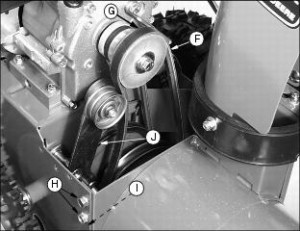

Snow Thrower Service – Lubricate All Moving Parts

The last thing you will want to do is to grease all points that require greasing. With fresh grease, you are protecting bearings, etc from exposure to the air and potentially rusting over the summer.

I like to spray the housing of the thrower with a fine oil to cover all parts that could rust. This is usually on the housing that has been scratched or bumped and exposed to the metal. Stopping rust from even starting will also make sure that it lasts a long time.

Even though spring and summer are calling, do this little chore now. Ensure that your snow thrower service is done now to prolong the life of your snow thrower.

It is pretty easy to complete a John Deere snow blower oil change. There are a few key steps you need to follow to ensure that the job is completed safely and properly. We will cover these in this post, but the main thing to do is to review your snow blowers manual. This will confirm the type of oil to use. How much oil to use and how often the oil should be changed. For most consumers, once a year is typical based on limited usage over the winter. We suggest doing the oil change in the fall so that you have fresh oil in the crankcase for the coming season. If you use the snow blower for commercial services, you should change the oil more often.

It is pretty easy to complete a John Deere snow blower oil change. There are a few key steps you need to follow to ensure that the job is completed safely and properly. We will cover these in this post, but the main thing to do is to review your snow blowers manual. This will confirm the type of oil to use. How much oil to use and how often the oil should be changed. For most consumers, once a year is typical based on limited usage over the winter. We suggest doing the oil change in the fall so that you have fresh oil in the crankcase for the coming season. If you use the snow blower for commercial services, you should change the oil more often.